To meet the functional and ergonomic requirements of modern industrial enclosure and cabinet design enclosure designers will want to identify the ideal hinge for their application. With so many variations in hinge design, material, and function, how does the design engineer identify the ideal hinge?

Beyond some of the more obvious design considerations, like hinge size (hinges should be large enough to hold the weight of the door but not so large as to hinder its use), and hinge colour (probably black, occasionally white, any other colour can be produced but won’t be available off-the-shelf), there are some hinge characteristics which are less obvious and require more consideration. Read our guide to find out how to choose the ideal enclosure hinge for your application.

Jump to a section:

- Enclosure hinge material

- Enclosure hinge mounting type

- External enclosure hinges

- Concealed enclosure hinges

- Lift-off hinges

- Removable hinges

- Detent hinges

- Positioning hinges

- Hinge comparison table

1. Enclosure hinge material

Enclosure hinges are normally manufactured from metal or plastic. Zinc is a common choice for metal enclosure hinges, thanks to its high strength-to-weight ratio and favourable resistance to corrosion. Zinc plated steel is strong, durable and cost effective, while stainless steel offers the greatest strength and corrosion resistance.

Plastic hinges are generally injection moulded thermoplastic, with nylon and acetal being the most common material. Nylon and acetal are strong, reliable plastics, and under most circumstances are perfectly capable of providing a long service life and ample resistance to chemicals, solvents and heat.

While plastic hinges have the advantage of lower weight and cost, metal hinges are stronger, more durable, and better able to support larger and heavier doors.

2. Enclosure hinge mounting method

Mounting your enclosure hinge will usually be via one of three methods: bolts and nuts, rivets, or welded.

Most hinges will attach with bolts (or machine screws) through the hinge, door and frame, and then fastened with a washer and nut on the rear. This method is simple, reliable, and allows for the door to be removed. Hinges like our Model 17 HI include integrated threaded studs which have the benefit of removing the screw head and improving security.

Rivets are quick, cost effective and strong. However in order for the hinge or door to be removed the rivet will need to be drilled out and replaced.

Welding is permanent, strong, and is often automated as part of the enclosure manufacturing process. For large enclosures, and large scale manufacturing, welding is often the optimal solution. It is however permanent, and removing or replacing the door will require much more work than via screws or rivets.

3. External enclosure hinges

As you might expect, enclosure hinges are installed either on the exterior or interior of an enclosure door. Some hinges can be installed both internally and externally, and some hinges can only be mounted internally or externally.

Mounting a hinge externally is the most straightforward method and gives the designer the widest choice of hinge type, size, and material. Designers should note that some features, such as detents and adjustable torque, are only available with externally mounted hinges.

4. Concealed enclosure hinges

Hinges which are mounted internally are generally known as concealed hinges. Concealed hinges have the advantage of greater security, thanks to the hinge and mounting hardware being concealed by the enclosure door. Concealed hinges also shield the hinge and mounting hardware from the environment, and in many cases will increase reliability, reduce maintenance, and improve service life.

5. Lift-off enclosure hinges

6. Removable enclosure hinges

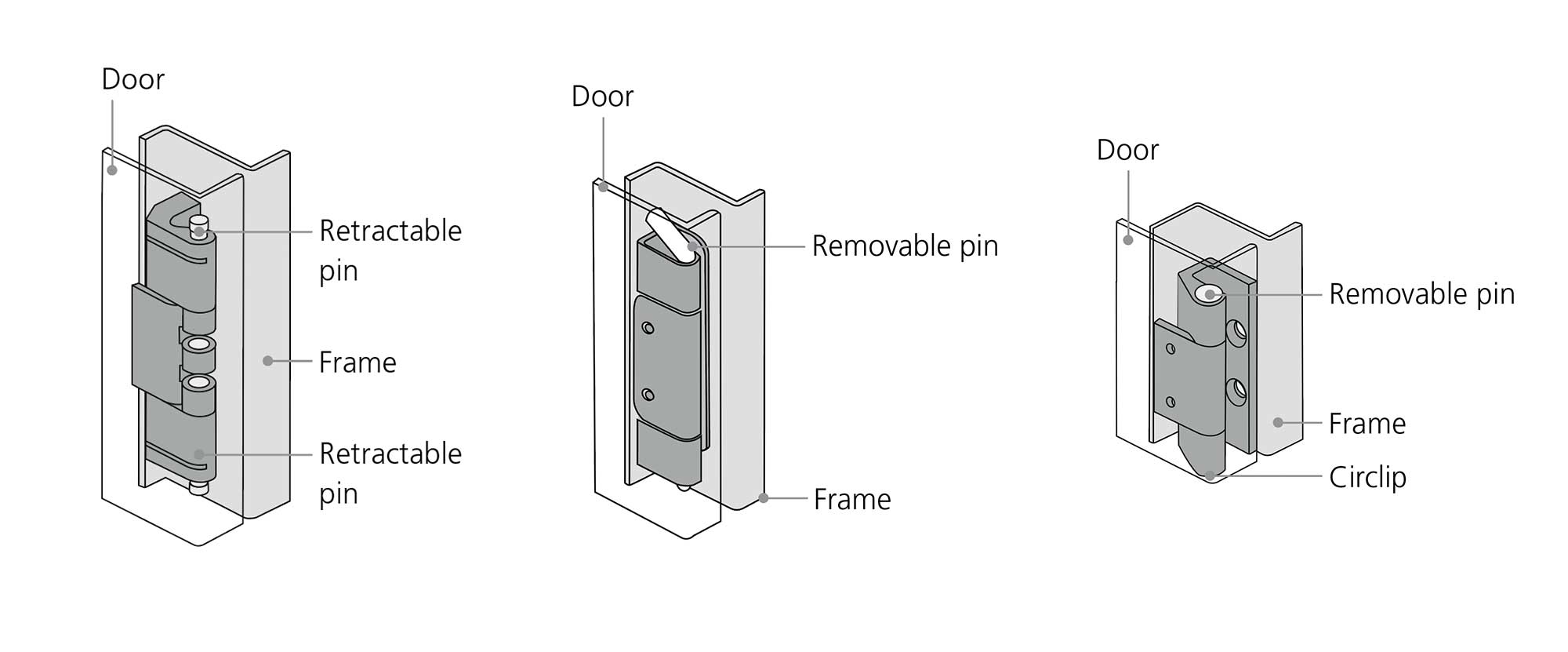

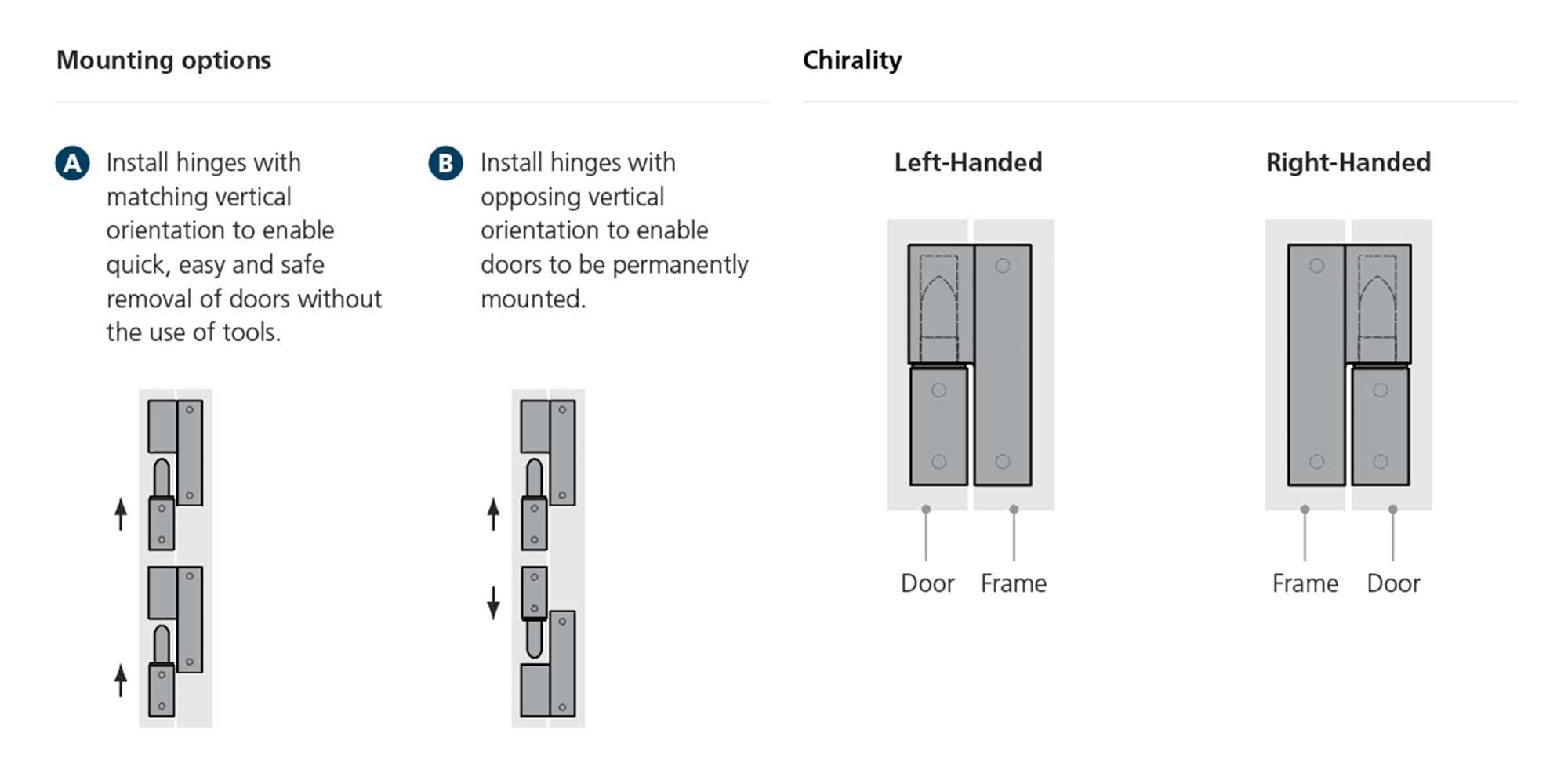

Removable hinges also allow the door to be quickly and easily separated from the enclosure. Removable hinges vary in the ease of which a door can be removed. In some applications, the door may only need to be occasionally removed, in others the door is frequently removed and therefore the ease of removal is more important.

Our removable hinges vary from simple lift-off hinges, to hinges with retractable pins, and hinges with pins which are removable but secured in place with a circlip and will require circlip pliers to remove.

7. Detent hinges

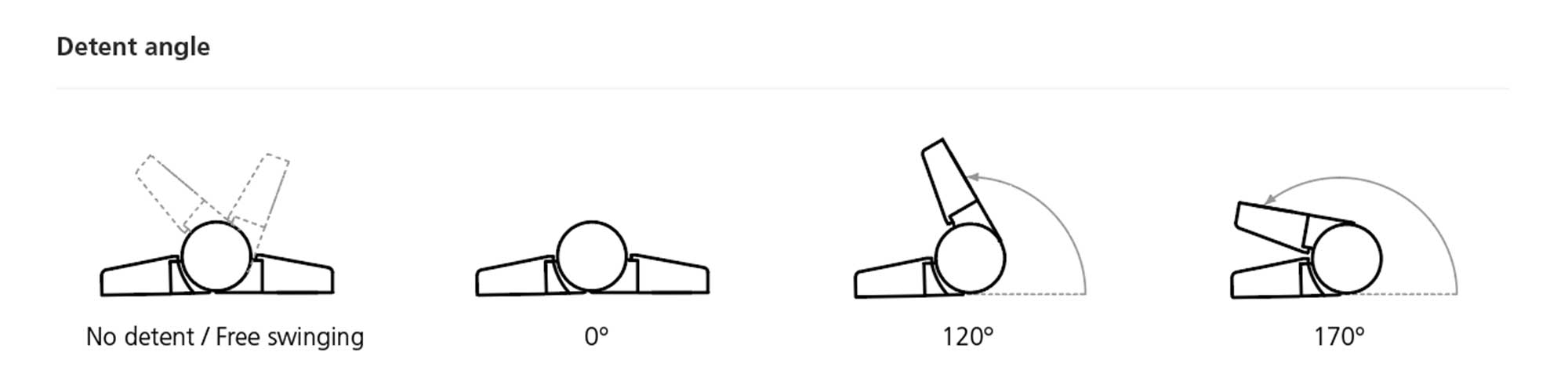

Detent hinges are designed to give hands-free access to the interior of enclosures and cabinets. The hinge ensures a door remains in a fixed, open position, without the need for secondary mechanical support such as a gas strut. This reduces the total number of components required and prevents additional hardware from taking up space inside the enclosure or cabinet.

8. Positioning hinges

Positioning hinges (also known as friction hinges) fall into one of two categories, constant torque hinges and adjustable torque hinges.

Constant torque hinges feature a constant rate of torque throughout their range of motion. This constant torque provides sufficient resistance to hold lightweight cabinet and enclosure doors open at a position that is convenient to the user.

Adjustable torque friction hinges provide similar functionality to constant torque friction hinges but with the added benefit of an adjustment screw which gives fine control over the frictional holding torque.

Adjusting the screw changes the level of resistance required to open and close the hinge and allows lids, doors and panels to be held open at any angle. Once adjusted, the positioning torque stays consistent throughout the full range of motion and will hold doors steady in position.

9. Enclosure hinge comparison table

| Advantages: | Applications: | |

|---|---|---|

| Lift-off hinges - When two or more hinges are mounted in the same orientation then the door can be removed to improve access - Mounting hardware is hidden behind door - Available in several configurations: inline, offset and adjustable View lift-off hinges | - Telecomms cabinets - IT & Server cabinets - Machine building - HVAC |

| Removable hinges - Enable quick and easy removal of doors - With door removed access is improved - Various types available, suited to regular or occasional door removal View removable hinges | - Telecomms cabinets - IT & Server cabinets - Machine building - HVAC |

| Concealed hinges - Conceals hinge from external environment - Hides mounting hardware - Improves security View concealed hinges | - Telecomms cabinets - IT & Server cabinets - HVAC |

| Detent hinges - Integral detents will hold door open at specific angles - Available with a detent at one angle or multiple angles - Removes the need for additional hardware such as gas struts View detent hinges | - Telecomms cabinets - IT & Server cabinets - HVAC |

| Positioning hinges / friction hinges with constant and adjustable torque - Hold doors open at any angle - Removes the need for additional hardware such as gas struts - Variants available with constant torque and adjustable torque for fine tuning View positioning hinges | - Telecomms cabinets - IT & Server cabinets - HVAC - Audio & Lighting Equipment |

| Surface mounted hinges - Simple installation - Suited to applications where door and panel are flush View surface mounted hinges | - Telecomms cabinets - IT & Server cabinets - Machine building - HVAC - Construction equipment |